Smart Weighing Scales Kampala

Floor Weighing scales calibration procedure in Uganda

Floor Weighing scales calibration procedure in Uganda

Couldn't load pickup availability

Floor Weighing Scales Calibration Procedure in Uganda

Accurate floor weighing scales are essential for warehouses, factories, agro-processing industries, and logistics companies in Uganda. To ensure precision, compliance with UNBS standards, and long-term functionality, businesses must follow a professional floor weighing scales calibration procedure. Trusted providers like Smart Weighing Scales Kampala

offer certified calibration, repair, and maintenance services nationwide.

Why Calibration is Essential

-

Accuracy & Precision: Ensures correct weight readings, preventing losses due to under-delivery or over-delivery.

-

Legal Compliance: UNBS requires regular calibration for scales used in trade and commercial activities.

-

Extended Lifespan: Proper calibration reduces strain on load cells and electronic components.

-

Operational Efficiency: Minimizes downtime caused by misreadings or scale failures.

Calibration Services by Smart Weighing Scales Kampala

provides professional calibration services for all types of floor weighing scales, including:

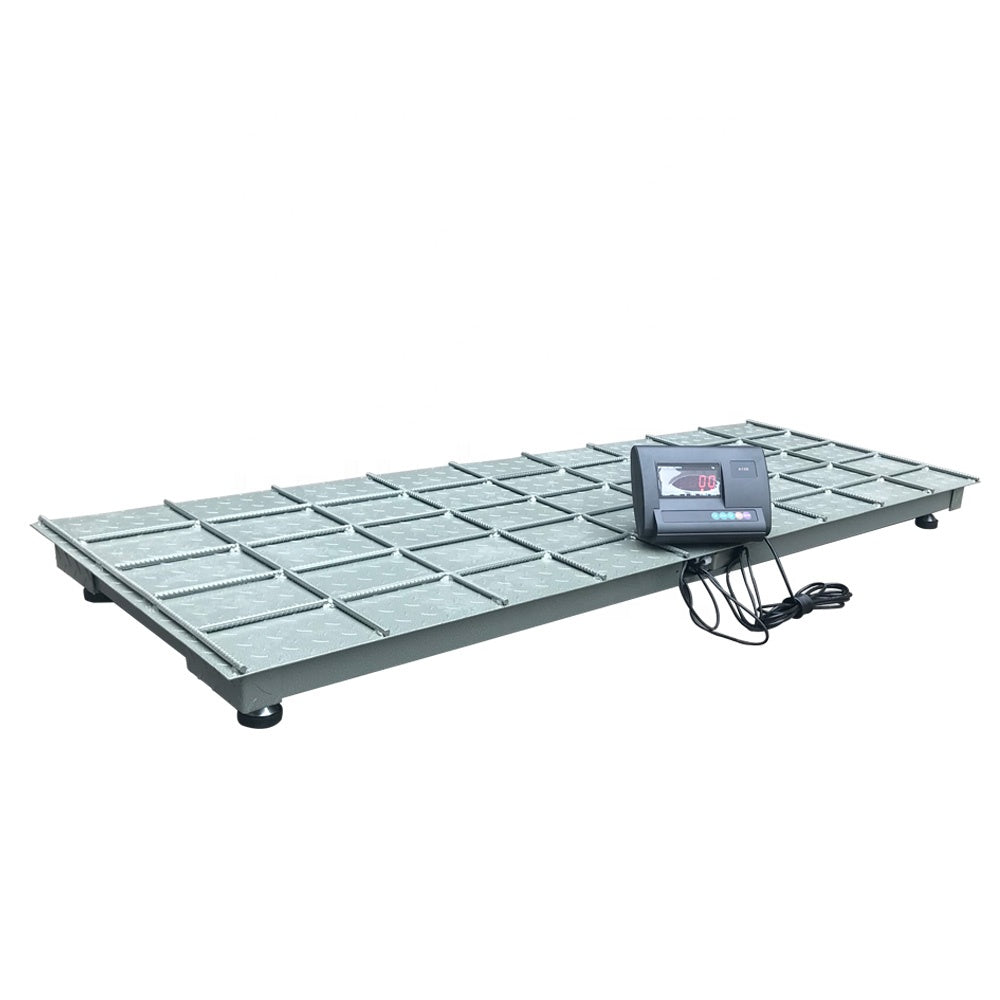

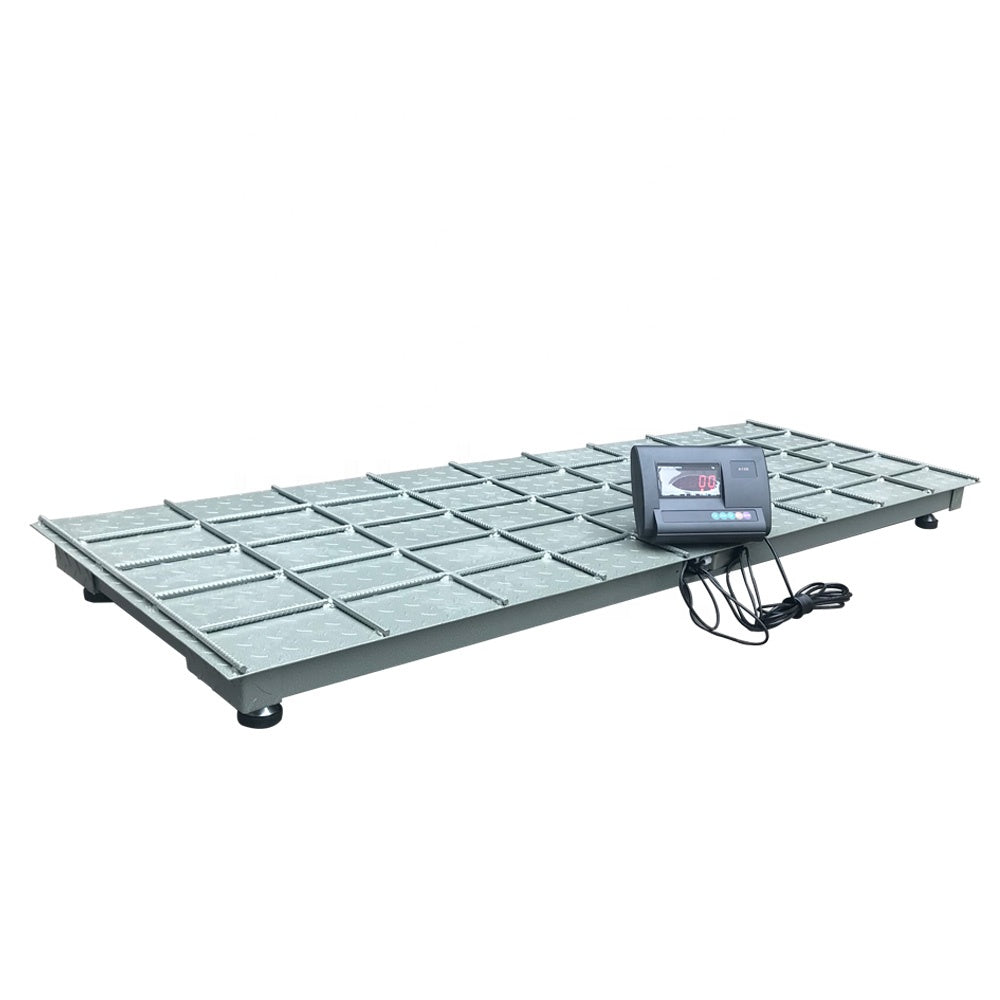

Platform Scales: Industrial floor platform scales

-

for warehouses and factories.

-

Heavy-Duty Scales: High-capacity floor scales up to 10 tons for industrial operations.

-

Warehouse Scales: Medium-duty scales for storage and logistics operations.

🔹 Calibration Procedure

-

Inspection & Setup:

-

Verify the scale platform is level and free of debris.

-

Inspect load cells, cables, and digital indicators for damage.

-

-

Warm-Up & Zeroing:

-

Power on the scale and allow it to stabilize.

-

Zero the scale to remove any residual weight influence.

-

-

Test Weight Application:

-

Apply certified test weights at multiple points (25%, 50%, 75%, 100% of capacity).

-

Record readings and compare with actual weight values.

-

-

Adjustment & Tuning:

-

Adjust digital indicators or mechanical components to correct deviations.

-

Recalibrate load cells if required.

-

-

Verification:

-

Repeat test weights to confirm accuracy across the full scale range.

-

-

Certification:

-

Issue a UNBS-compliant calibration certificate for trade use.

-

-