Smart Weighing Scales Kampala

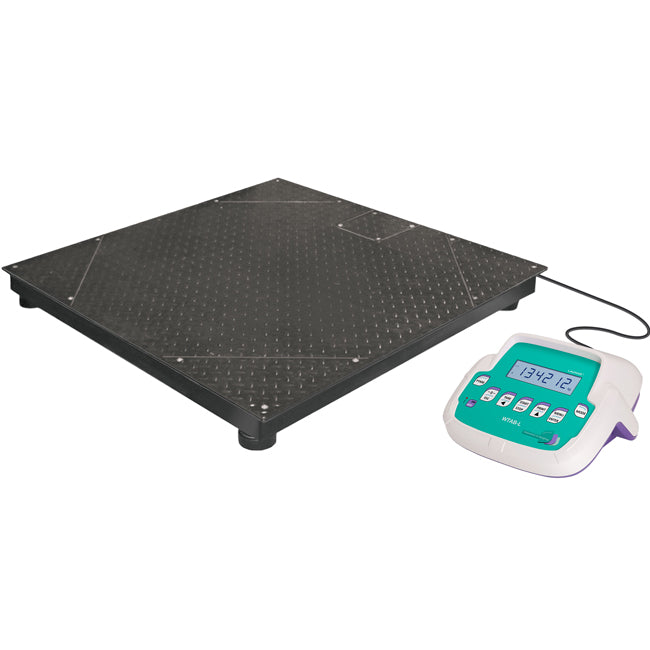

Floor Platform Weighing scales calibration in Uganda

Floor Platform Weighing scales calibration in Uganda

Couldn't load pickup availability

Floor Platform Weighing Scales Calibration in Uganda

In Uganda’s warehousing, industrial, agro-processing, and logistics sectors, floor platform weighing scales play a crucial role in daily operations. However, even the most advanced digital or mechanical scales require regular calibration to maintain accuracy, comply with UNBS standards, and avoid costly measurement errors. That’s why many businesses rely on Smart Weighing Scales Kampalaand Eagle Weighing Systemsfor professional floor platform weighing scales calibration in Uganda.

Why Calibrate Floor Platform Weighing Scales?

-

Accuracy & Trust: Prevents errors in production, sales, and logistics.

-

Compliance: Ensures your weighing equipment meets Uganda National Bureau of Standards (UNBS) requirements.

-

Efficiency: Accurate readings streamline warehouse and factory operations.

-

Cost Savings: Reduces losses caused by overweighting or underweighting.

-

Extended Equipment Life: Regular calibration reduces wear and protects load cells and indicators.

-

Calibration Procedure

At Smart Weighing Scales Kampala and Eagle Weighing Systems, calibration follows a systematic procedure designed for maximum accuracy:

-

Inspection & Preparation

-

Check the weighing platform, load cells, wiring, and digital display.

-

Confirm the scale is level and placed on a stable surface.

-

-

Zero Calibration

-

Reset the scale to zero before testing.

-

Ensure no external weight affects the balance.

-

-

Applying Standard Test Weights

-

Use UNBS-approved calibration weights.

-

Test at different load points (25%, 50%, 75%, and 100% of scale capacity).

-

Compare displayed values against certified weight standards.

-

-