Smart Weighing Scales Kampala

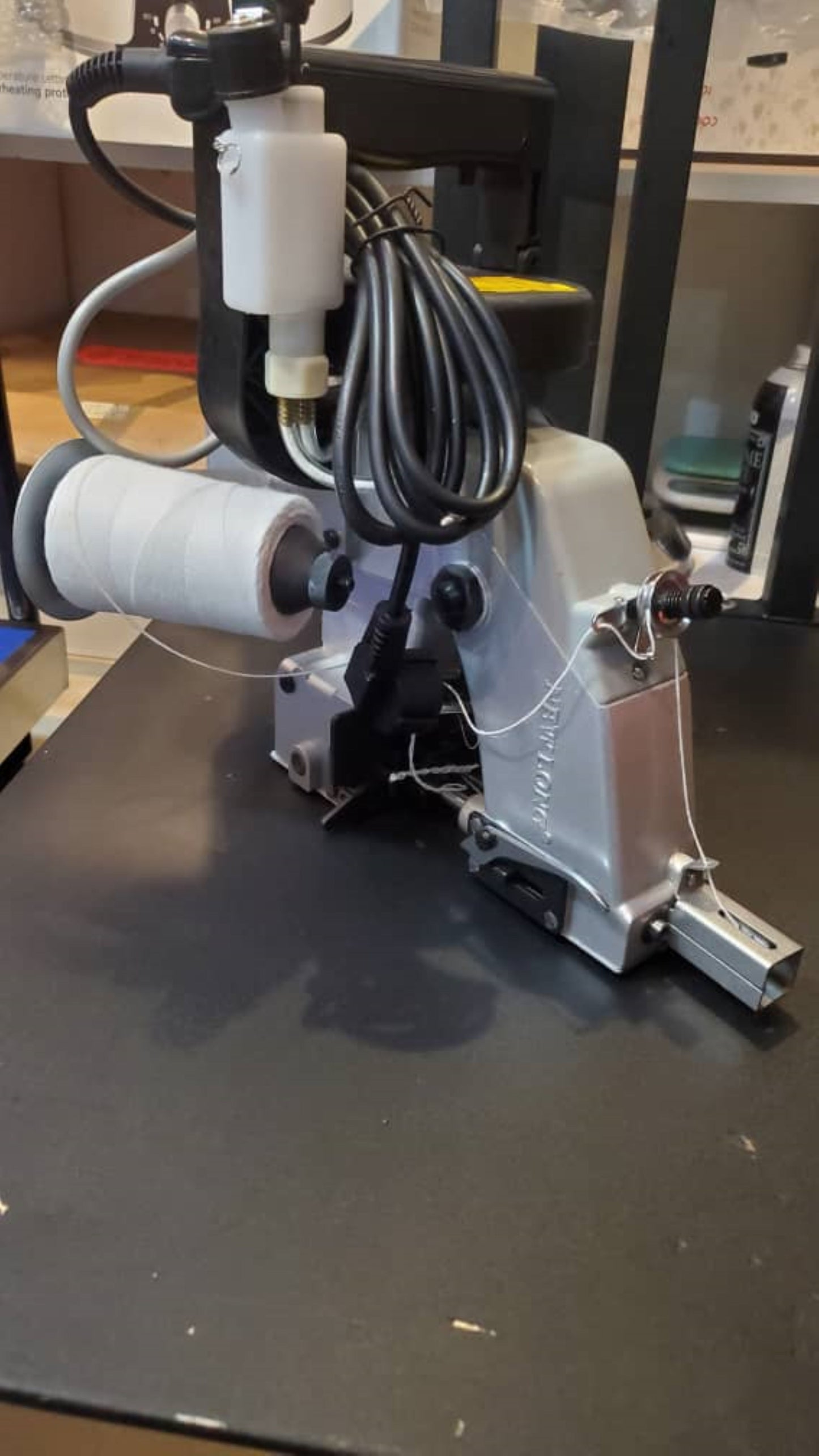

Commercial Bag Closer Machine for Fish Feed and Livestock Feed Mills

Commercial Bag Closer Machine for Fish Feed and Livestock Feed Mills

Couldn't load pickup availability

Commercial Bag Closing & Stitching Machine for Fish Feed and Livestock Feed Mills in Uganda

If you operate a feed‑mill—producing fish feed, poultry feed, cattle feed, or livestock rations—and are packaging your product in sacks for sale or distribution, having a commercial‑grade bag closing (bag‑sewing) machine is essential. A purpose‑built machine ensures your filled bags are consistently sealed, reduces product losses, enhances presentation, and supports operational efficiency. Below is the detailed overview.

Why It’s Crucial for Feed Mills

-

Feed sacks often contain heavy loads (25 kg, 50 kg or more) and are made of woven polypropylene (PP), laminated woven sacks or thick paper bags. Poorly sealed sacks risk spillage, moisture ingress, pest infestation, and reduced shelf life.

-

In a feed production environment the bagging rate may be high — milling lines need fast, reliable sealing to avoid bottlenecks after filling.

-

For livestock/fish feed operations, product integrity affects customer trust (farmers expect intact, full bags), so the bag closing machine contributes to quality assurance.

-

In Uganda’s industrial contexts (dusty mills, humid environments, continuous shifts) you want a machine built for durability, easy maintenance and local parts access.

Key Features to Look For

When selecting a machine for this application, check for:

-

Material compatibility: The machine must be rated for feed‑sack materials (woven PP, laminated PP, multi‑wall paper, jute, etc). Many models list “food, pet, animal” industries among compatible applications. Smart Weighing Scales Kampala+2TilyExpress+2

-

High throughput/stitch speed: To keep pace with bagging operations. For example, one portable model claims capacity ~250‑300 bags/hour.

-

Durable, industrial build: Heavy‑duty motor (e.g., 90 W or more), high‑quality steel components, heat‑treated wear parts, enclosed motor housing for dusty/humid environments. Smart Weighing Scales Kampala

-

Automatic thread cutter / one‑step operation: Reduces operator time and improves consistency. Smart Weighing Scales Kampala

-

Local support/spare parts availability: Important for feed mill operations that can’t afford long downtime.

-

Clear pricing in UGX and local delivery: Ensures budgeting is accurate for Ugandan operations.

Example Products & Pricing in Uganda

Here are some relevant examples you can reference in Uganda:

-

Hanchen Cordless Bag Closer Sewing Machine: Price ~ UGX 813,431. Suitable for feed sacks, seed bags, woven PP.

-

Industrial Portable Bag Sack Stitching Sewing Machine Combo: Price ~ UGX 580,000 for agricultural/animal feed/chemical sectors.

-

Newlong Automatic Bag Closing Machine for Commercial Use: Price listed ~ UGX 2,400,000 for high‑capacity machines in Uganda.

-

Bag Closing Machine Electric Sewing Bag Closer (feed/animal/pet compatible): Price ~ UGX 500,000 via local supplier. Smart Weighing Scales Kampala

From those, for a feed‑mill application you might budget somewhere between UGX ~500,000 to UGX ~1,000,000+ depending on throughput and automation level.

Application in a Feed Mill Setting

Here’s how you’d integrate it:

-

After your feed mixer/filler, a weighed bag (say 50 kg feed sack) comes to the bag‑closing station.

-

The operator places the bag under the machine’s closing head; the machine stitches the open top rapidly and with consistent seam quality.

-

The sealed bag moves to palletising or storage. With a good machine you reduce re‑work of bags that may leak or open, reducing waste and enhancing throughput.

-

Regular maintenance (lubrication, thread/needle replacement) ensures uptime, which is critical in industrial feed production.

Buying Tips for Uganda

-

Match capacity to your bag volume: If you’re sealing hundreds of bags per hour, choose the higher‑speed model (UGX ~1M+). For lower volume, the UGX 500k‑600k range may suffice.

-

Check bag size/material compatibility: Ensure the machine accommodates the sack width/height and uses the correct stitch type for your bag material.

-

Ensure spare‑parts locally: Needles, thread, motor servicing — ask about local parts stock.

-

Plan for maintenance: Even “industrial” machines need periodic servicing; budget for that.

-

Consider operator ergonomics & safety: Feed mills may have dusty/humid environment; machine should handle that.

-

Confirm warranty/support: Even in Uganda, good suppliers offer minimal guarantee or parts backup.

Final Recommendation

For fish feed and livestock feed mills in Uganda, a commercial‑grade bag closing and stitching machine is not just a convenience — it’s an operational necessity. With prices starting as low as UGX ~500,000 and going up into the UGX 1M+ range for high throughput models, you should select a machine rated for your bag material and volume, from a reliable supplier who can support you locally.